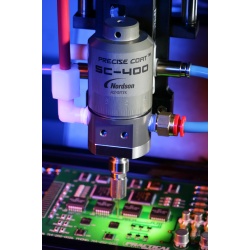

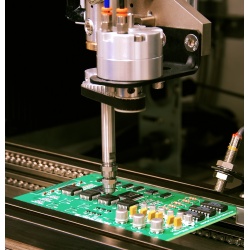

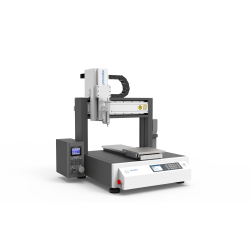

The reliability of printed circuit boards largely depends on the quality of the conformal coating. The Select Coat® SL-940 Series provides the high-quality coating results and productivity you need for your automated batch or in-line process. A robust and flexible feature set simplifies and enhances your process by providing process control and traceability, improving setup consistency, supporting faster changeover, reducing operator interaction, and increasing throughput. EasyCoat® system software supports on and offline programming and allows you to set process parameters, measure, record, and trace process outcomes. As a trusted coating partner for over 35 years, we understand your time is valuable and that the equipment you select determines your products’ quality, cost, and reliability.The road to reliability should not be complicated. We have combined our industry-leading Select Coat SL-940 Series features and options into standard Trim Packages, including Essential Option Bundles, to streamline equipment selection. With Trim Packages, you’ll get the equipment and application support you need with minimal lead time.

Features and Benefit

- Choose from several standard conformal coating trim packages that optimize productivity, selectivity, and process flexibility

- All Trim Packages support low-viscosity solvent-based (25 – 125 cps) and medium-viscosity solid (125 – 1200 cps) fluid applications.

- Trim Packages also feature Essential Option Bundles tailored for quick changeover, maintenance monitoring, moisture sensitivity, and Industry 4.0 connectivity.

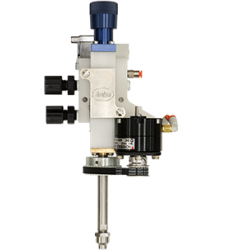

- Support up to three applicators.

- Easy-to-clean stainless steel surfaces are resistant to the effects of strong agents.

- Downdraft air management system safely removes VOCs to meet Low Flammable Limits (LFL) standards.