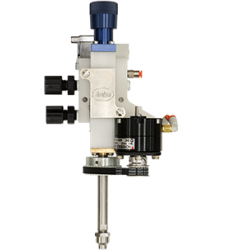

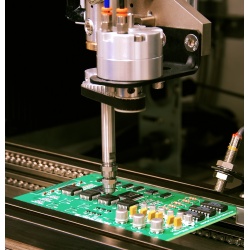

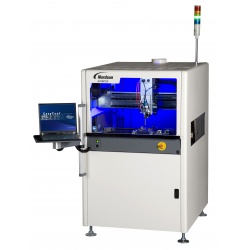

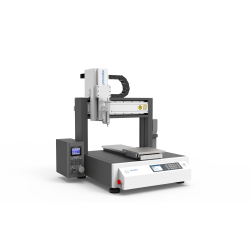

The Core and Prime SC-400 PreciseCoat® Fluid Systems are ideal for applying coating materials to highly selective areas. The applicator is designed for coating small substrates, substrates with high- component density, and situations where there are tight tolerances between coated and uncoated areas. The needle design with jetting action and fast pulse- width modulated control allow the SC-400 jet to reach locations that cannot be accessed by other applicators. Small volumes and better material control deliver line widths down to 1.2 mm (0.05 in.) wide. The need for masking is eliminated because the flow is so closely controlled. Easy Coat software creates process synergy between the unique applicator and platform design by providing routines and validation steps to define the optimal start and stop points during production. This allows coating materials to be consistently applied to the exact programmed locations.

Features and Benefits

Fine, smooth lines are generated through the use of shooting-on-the-fly technology available in Easy Coat® software

Reaches locations not possible with other applicators

Dot sizes down to 1.2 mm (0.05 in.)

Thin film builds down to 15 µm – with solvent based materials

Fast, up to 500 mm/sec (20 in./sec)

Easy to disassemble and maintain

Optional Needle Sensor module – verifies needle tip location

Optional Four-Position Tilt adapter – features the standard vertical position and tilts the applicator at 30 degrees in four positions

Available in Dual-Simultaneous configurations – coating process time is reduced by 50%

Available in a Prime Viscosity Control configuration – heated fluid system