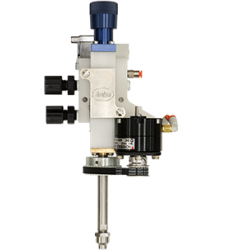

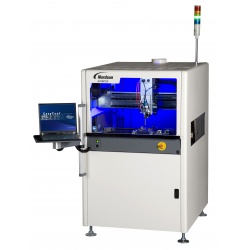

The SC-280 Film Coater Fluid Systems optimize throughput and increase yield by delivering high velocity, excellent edge definition, improved response time and on/off rates, and the ability to use a variety of coating widths. When combined with the SL-940 Prime Process Controls option, the SC-280 Prime fluid system can utilize multiple fan patterns within one program. Easy Coat® software creates process synergy between the applicator and platform design through routines and validation steps that are used to define the optimal start and stop points during production. The film coater provides automated, selective application of conformal coating materials with viscosities less than 100 centipoise. Programmable applicator modes – spots, lines, and area coverage – provide powerful coating results. The SC-280 ensures a consistent fan pattern – even after idle – through the unique design that circulates heated fluid through the applicator extension maintaining a consistent nozzle temperature at all times. Programmers define the process temperature and the corresponding process limits in Easy Coat software. If the fluid temperature moves outside the defined process limits during production, the system triggers an alarm condition and operators can intervene to prevent potential errors. To optimize the Prime SC-280N and SC-280C Film Coater Fluid Systems for your production, you have a choice of two nozzles and two fluid reservoirs of either 1- or 5-gallon capacity. Fluid pressure is controlled electronically through Easy Coat software. The SC-280N and SC-280C programmable fluid pressure is contingent on the optional Prime Process Controls. The SC-280N Film Coater Fluid System is also available in a Dual-Simultaneous configuration. The SC-280 applicators are intended for use with the Select Coat® SL-940 conformal coating system.

Features and Benefits

High coating velocity up to 750 mm/sec

With a transfer efficiency of virtually 100 percent, the Film Coater applicator improves conformal coating utilization by 30- 50 percent

The non-atomized design minimizes common problems such as over-spray, masking, and rework

Wet coating thicknesses range from 125 to 750 µm (0.5 to 3 mils) for solvent-based materials and 0.1 to 0.2 mm (4 to 8 mils) for 100-percent solid materials

Stainless steel fluid path – compatible with a variety of conformal coating materials

Easy maintenance and setup routines

Simple conversion between non-circulating and circulating configurations – to meet future production needs

The standard Fourth Axis provides a 0 – 90 degree rotation of the fan pattern

Optional Fifth-Axis Tilt accessory increases accessibility to tight or difficult-to-reach areas by providing four tilted positions

Available in a Dual-Simultaneous configuration – reduces coating process time by 50%

The SC-280C heated, circulating fluid system provides closed- loop temperature control and allows viscosities to remain independent of the ambient environment