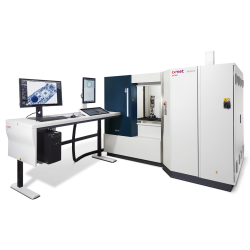

The FF20 CT is the expert microCT system for R&D, defect analysis, or CT metrology. It is designed for inspections of very small components and objects in the electronics industry, material science, and other research areas.

FF20 CT highlights

Accurate material analyses in laboratory applications

2D detail visibility of down to 150 nm with 190 kV transmission tube

Precise manipulation and temperature stability through granite base

Intuitive Geminy graphical user interface with touchscreens

Non-destructive testing with high energy

The smaller components become, the more important it is to achieve highly accurate, reliable X-ray and CT scans for quality assurance, process control, and small series inspections. The extremely compact high-resolution system Comet Yxlon FF20 CT is designed specifically for the inspection of very fine parts and internal structures. With comparatively high energy of 190 kV, even dense items can be analyzed to the smallest detail.

Water-cooled 190 kV transmission tube

The 190 kV nano-focus transmission tube achieves a detail visibility in radioscopy (2D) of down to 150 nm. While its water-cooled target and coils allow for quick temperature balance and highest focal spot stability, four modes enable the optimal adjustment of the focal spot size in relation to power. In addition, the granite-based manipulator of the FF20 CT system guarantees temperature stability and smallest thermal expansion for maximum precision and accuracy.